Sample Storage and Distribution

One of the primary examples of controlled compound storage in a validated environment is the COVID-19 vaccine. Stored in a carefully monitored environment, it’s necessary to keep it cold. That’s why counties start scrambling to rapidly distribute vaccines when appropriate storage facilities break down.

This—the controlled storage of compounds in a validated environment—is the basis for all successful drug discovery operations.

Major challenges are faced by compound managers. These days, the stakes have never been higher, as new drugs are being discovered daily. Of course, storage temperature and environmental conditions have a significant effect on these compounds.

The end goal? To establish an efficient chain of condition, custody, and identity while rapidly providing compounds as solids or liquids. Temperature-controlled storage is vital for the delivery of these sensitive biological assays.

What Solutions Do We Offer?

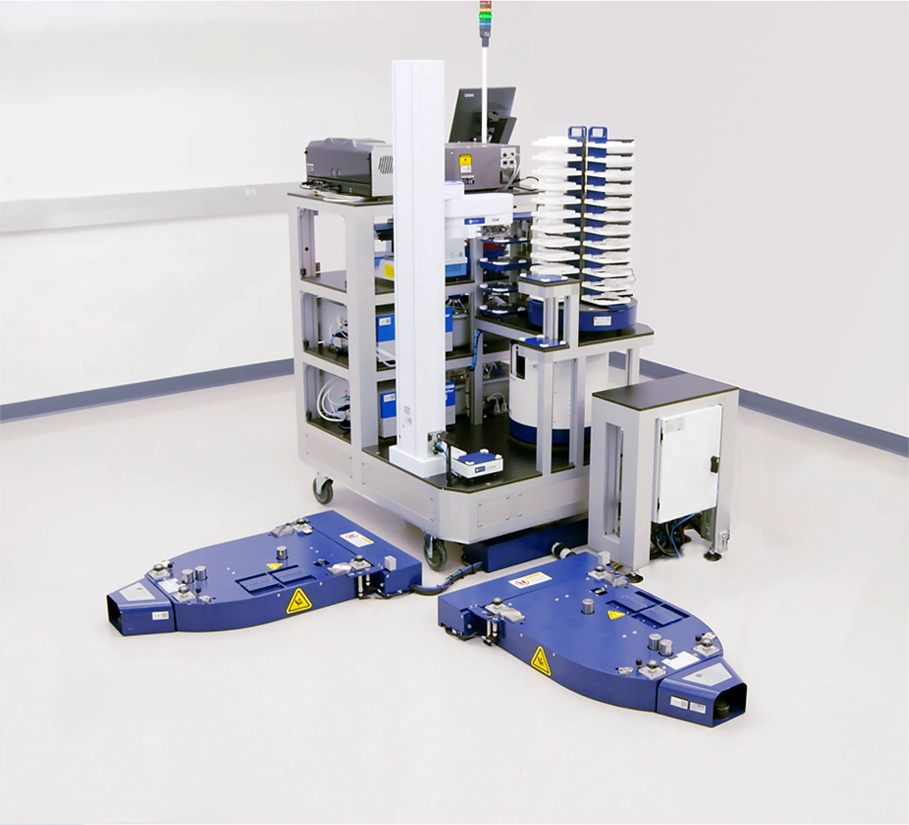

HighRes offers a variety of solutions for integrating these large-scale sample stores into downstream processing operations. These can range from direct integrations of stores into compound delivery automation systems, to the novel concept of using docking technology to transfer tube racks and plates from your compound store to separate processing systems.

Our automated solution systems provide the following perks:

- Reduced turnaround time

- Greater overall throughput and reduction of manual processing

- Enables direct integration with automation platforms

- Supports any samples (tubes, vials, and plates) stored on SBS format racks

Our solutions provide a powerful platform for handling daily compound management operations, keeping track of sample movements, and meeting downstream research goals. Our connected approach leverages the strength of multiple vendors. In this way, we achieve a seamless automated workflow—which leads to improved timelines for screening and hit identification. This protects the integrity of the compound collection in an automated storage and retrieval system.