Collaboration within reach

CoLAB™

The CoLAB Concept

Working with laboratory automation has always required that, for safety reasons, the operators of the system needed to be physically isolated from the automation and robotics. This safety issue has necessitated the use of extensive, bulky shielding to protect and isolate people from their laboratory automation.

This requirement for shielding has not only wasted a lot of valuable lab space, but it has also made the interaction between users and their laboratory automation systems less than ideal. Trouble shooting, moving or reconfiguring a system or any of its components has always been a major undertaking, resulting in significant laboratory downtime and loss in productivity.

Evolving Automation with CoLAB

Now, HighRes Biosolutions® has built upon its innovative history of laboratory automation flexibility to develop the CoLAB concept of laboratory automation. Simply put, CoLAB automation allows safe, direct interaction with laboratory automation. This change in philosophy enables operators to work more closely with their automation systems than ever before, and obviates the need for extensive shielding for a laboratory automation system.

The CoLAB concept allows operators to:

Interact with lab automation like never before.

Utilize advanced automation style and safety capabilities.

Respond quickly to changing requirements.

The CoLAB Family

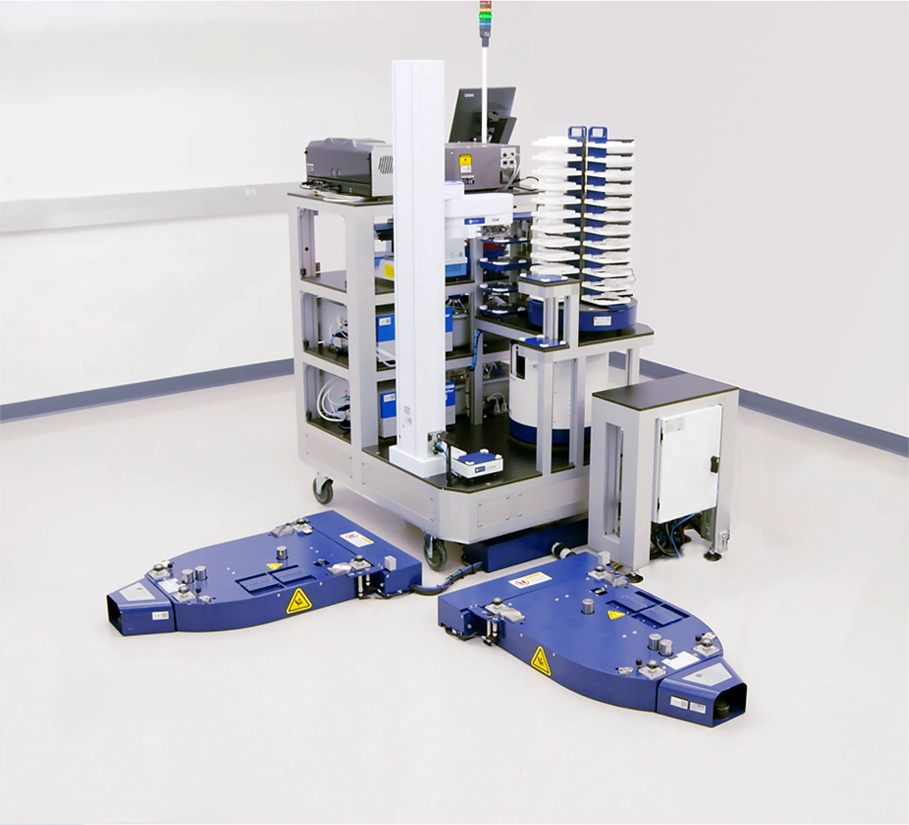

Built around truly collaborative robotics, each member of the CoLAB family is designed to be used in the same laboratory space as its operator. Well equipped with a variety of automatic safety features, these systems are available for either new lab automation systems or as dynamic extensions of an existing system.

The CoLAB systems utilize hyper-intelligent motion and load sensing technology to slow, and even stop, when they detect a change in their operating environment or come into contact with even the slightest amount of resistance. The previously released ACell system has similar safety features that also make it for use without shielding.

CoLAB System Comparison

| CoLAB Systems | Traditional Systems | Semi-Automated Systems | |

|---|---|---|---|

| User Interaction | Direct | Indirect | Indirect |

| Safety Measures | No Shielding Required | Device and System Shielding Required | Device Shielding Required |

| System Reconfiguration | Very Fast Minimal Effort |

Slow Significant Effort |

Moderate Some Effort |

| Degree of Automation | Full system automation | Full system automation | Device level automation |

| Trouble Shooting | Immediate | Slow Kill Switch Shielding Removal |

Power down Shielding Removal |

| Configuration Availability | CoLAB Microstar (6-sided) CoLAB NanoCell CoLAB Flex ACell |

All Systems | Device Level Only |

Friendly

Traditional laboratory automation has always required extensive shielding and safety measures that have isolated users from their systems. A CoLAB system changes that requirement. Light weight, safe, and powerful, with built in automatic safety features, a CoLAB enabled system allows you to get closer to your automation than ever before without any fear.

Safety Features

| Robotic Arm Environment Sensors | Integral laser sensors constantly monitor robotic arm operation in a 360° hemisphere up to 2 meters in radius |

|---|---|

| User Defined Slow Speed/No Go Zones | Robotic arm can be programmed to operate at <250mm/sec speed in any area. Robotic arm can be programmed to not operate in a defined area |

| Safety Styled Robotic Arm | Smooth external surface with no sharp edges or pinch points |

| Robotic Arm Motion Brakes | All 7 axes have pressure sensors and individual brakes |

| Automatic Robotic Arm Stop | Robotic Arm completely stops in less than 0.25 secs (~7mm distance) when encountering any resistance >0.1 lb |

| Repeatability | Robotic arm will repeatedly return to the same position within +/- 0.1mm |

Inspire

The core robotics of a CoLAB system were designed for Space. But you don’t have to be an astronaut to utilize the automation capabilities of this system. With a long reach and a 7 axis range of motion, a CoLAB system provides a high load capacity robotic arm that can integrate a whole host of devices and form the core of an extremely capable automation platform.

The CoLAB Systems Availability

| MicroStar CoLAB | NanoCell CoLAB | CoLAB Flex | ACell | |

|---|---|---|---|---|

| Robotic Arm | CoLAB | CoLAB | ACell or CoLAB | ACell |

| Number of Integrated Devices | Up to 6 devices | Up to 4 devices | 4 levels of devices 1-8 devices |

1-3 devices |

| Mobility | Not mobile 6 sided pod with docks |

Not Mobile 4 sided pod with docks |

4 levels of devices Mobile cart |

N/A |

| Shielding Requirement | None | None | None | None |

| System Control Software | Cellario Cellario Connect |

Cellario Cellario Connect |

Cellario Cellario Connect |

Cellario Cellario Connect |

| Time to Reconfigure System | Minutes | Minutes | Minutes | N/A |

Respond

Automation technology does not stand still. To answer the challenge brought on by changes in assays and technologies, a CoLAB system builds upon the HighRes Biosolutions philosophy of flexibility and mobility in automation system design and implementation. Another useful feature of a CoLAB system is its ability to use a free floating teach mode for the robotic arm to teach it new positions when the system configuration is changed. With a CoLAB system in place, changing system configurations is fast and easy.