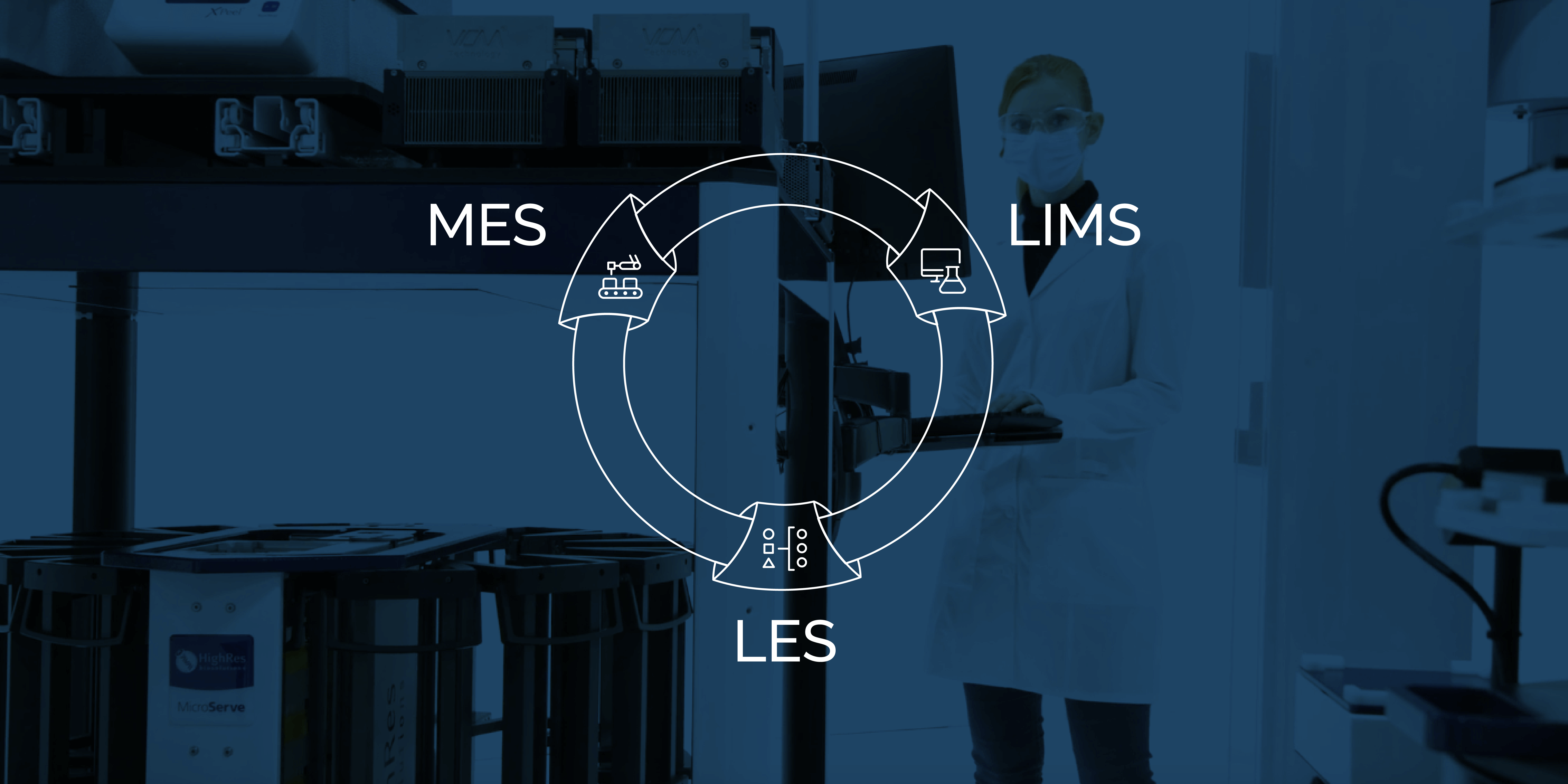

Understanding LIMS, LES, and MES

LIMS, LES, and MES are indispensable informatics systems that establish order, support robust efficiency, and drive data-driven insights in scientific and manufacturing workflows. While these systems share some overarching benefits, they serve distinct roles in modern pharma and biotech operations.

This guide is designed for IT Business Partners, Lab Operations Managers, and Scientists seeking to understand how these systems function, where they are best applied, and how to select the right system for their needs.

Laboratory Information Management System (LIMS)

A Laboratory Information Management System (LIMS) is software designed to enhance efficiency, accuracy, and reliability in research and development (R&D) and quality control laboratories.

Key Functions of LIMS Include:

- Sample & Data Management – Tracks sample activities throughout the sample lifecycle, centralizing data for easy retrieval.

- Inventory & Equipment Management – Manages reagents, consumables, and instrument maintenance schedules.

- Protocol Standardization – Ensures assay procedures remain consistent across users and sites.

5 Key Benefits of Laboratory Information Management Systems (LIMS)

1.- Centralized Data Management for Enhanced Efficiency

A Laboratory Information Management System (LIMS) provides a unified platform for managing all laboratory activities, creating a single source of truth for your organization. This centralization eliminates the scattered nature of data stored across spreadsheets, notebooks, and disparate systems. The ability to search through a database allows teams to quickly retrieve critical information, whether it's reprinting a years-old certificate of analysis or analyzing trend data from specific tests conducted over extended periods. Workflow Standardization and Compliance.

LIMS solutions excel at defining and enforcing standardized workflows, ensuring that laboratory procedures are consistently followed across all operations. This standardization is crucial for maintaining regulatory compliance with requirements such as ISO17025, FDA 21 CFR Part 11, and GxP standards. By implementing a LIMS, laboratories can:

Enforce standard operating procedures to ensure repeatability and consistency in results

Manage staff training and competency records systematically

Track instrument maintenance and calibration schedules automatically

Document and manage corrective and preventative actions (CAPA) as part of quality improvement cycles.

2.- Error Reduction Through Automation and Integration

One of the most significant advantages of modern LIMS platforms is their ability to eliminate transcription errors through instrument integration. By connecting directly with laboratory equipment, from simple analyzers to complex chromatography and mass spectrometry systems, LIMS solutions can automatically capture data without manual intervention. This automation significantly reduces the risk of human error while increasing data integrity and reliability.

3.- Enhanced Sample Management and Traceability

LIMS provides sample tracking throughout the entire lifecycle, ensuring complete traceability from receipt to disposal. This capability is particularly valuable for genomics and other high-throughput laboratories where maintaining sample integrity and identity is critical. The system allows for:

Tracking sample activities and locations throughout the laboratory

Managing inventory of reagents and consumables related to sample processing

Standardizing protocols to ensure consistency across users and sites.

4.- Improved Operational Efficiency and Cost Reduction

Implementing a LIMS drives substantial improvements in laboratory efficiency, ultimately reducing costs and increasing productivity through more streamlined operations. The paperless approach eliminates time-consuming manual processes, allowing staff to focus on value-added activities rather than administrative tasks. Integration with other business systems, such as ERP and accounting platforms, further increases process efficiency across departments.

5.- Real-Time Data Access and Enhanced Collaboration

Modern LIMS solutions enable real-time access to updated protocols, reports, and results across multi-site enterprises. This accessibility fosters improved communication and collaboration among team members, regardless of their physical location. With centralized data storage, laboratories can:

Reduce downtime risks through readily available information

Enable seamless information sharing between teams and departments

Support data-driven decision making with accessible, accurate information, Scalability, and Adaptability for Evolving Needs

Highly configurable LIMS platforms offer the advantages of being tailored, adaptable, supportable, and upgradable throughout their lifecycle. This adaptability ensures that as laboratory needs evolve, the LIMS can be adjusted to accommodate new requirements without extensive redevelopment. The benefits include:

Supporting individual workflows per individual, group, or location

Accommodating both single-user operations and multi-national systems

Eliminating unnecessary workflow steps to improve efficiency.

Laboratory Execution System (LES)

A Laboratory Execution System (LES) is tailored for manufacturing and quality control environments where repeatability and workflow precision are critical.

Key Functions of LES Include:

- Guided SOP Execution – Walks users through each step of an SOP with visuals and mandatory input fields.

- Data Capture & Review – Integrates with lab devices to capture and verify data before sending it to a LIMS.

- Timestamped Recordkeeping – Ensures each step is recorded in sequence for traceability and compliance.

LES vs LIMS

Now that we have reviewed the functionalities of both LIMS and LES independently, it's helpful to compare how LES differs from LIMS to determine which system best fits your needs.

| Feature | LIMS | LES |

|---|---|---|

| Sample & Inventory Management | Yes | No |

| Workflow Execution Guidance | No | Yes |

| Data Standardization & Centralization | Yes | Yes |

| Visual SOP Instructions | No | Yes |

| Regulatory Compliance Support | Yes | Yes |

Note: LES is often integrated with LIMS to enhance workflow control.

Manufacturing Execution System (MES)

A Manufacturing Execution System (MES) is designed for real-time monitoring and control of pharmaceutical production workflows.

Key Functions of MES Include:

- Production Process Control – Tracks manufacturing steps and integrates with production equipment.

- Quality Control & Compliance – Ensures adherence to GMP, 21 CFR Part 11, and ISO regulations.

- Real-Time Equipment & Consumable Monitoring – Prevents downtime by tracking device health and reagent usage.

An MES functions similarly to a LIMS but focuses on manufacturing rather than R&D. Integrating MES with LIMS ensures a seamless transition from research to full-scale production by maintaining consistency across processes. It enables data continuity throughout development, technology transfer, and manufacturing, ensuring that critical information is preserved and accessible at every stage. Additionally, this integration allows for faster optimizations based on real-world production data, helping organizations refine workflows, improve efficiency, and accelerate time to market.

Choosing the Right System

Selecting the right informatics system requires careful consideration of workflow requirements, existing infrastructure, and future scalability. Start by identifying your primary need. Consider whether you are managing R&D samples with a LIMS, guiding lab workflows with an LES, or tracking production with an MES. Next, evaluate the integration needs of the system, ensuring compatibility with existing automation platforms, APIs, or cloud solutions. Additionally, consider the regulatory and compliance requirements, determining which industry standards the system must support. Finally, assess scalability and future-proofing to ensure the chosen solution can accommodate new instruments, data growth, and evolving workflows over time.

Conclusion

Modern life sciences operations require robust informatics solutions to streamline workflows, enhance compliance, and drive efficiency. Understanding the differences between LIMS, LES, and MES is key to selecting the right system for your needs.

By carefully evaluating how these platforms integrate into your research and production environment, you can build a future-ready digital infrastructure that eliminates inefficiencies, enhances data-driven decision-making, and accelerates innovation. Ready to transform your processes? Call us now to get started today!