Infinium XT assays are widely used in genotyping applications, requiring highly reliable amplification and precise liquid handling across multiple plates. Manual execution can limit throughput and increase variability, while automation provides the consistency and scalability needed for high-throughput genetics research.

At HighRes, we work with labs to design modular automation systems that not only execute complex workflows like Infinium XT, but also adapt to evolving assay requirements, consumables, and scaling needs. This write-up highlights a representative system designed to automate pre-amplification steps in Infinium XT workflows, including liquid transfers, reagent dispensing, plate sealing, and storage.

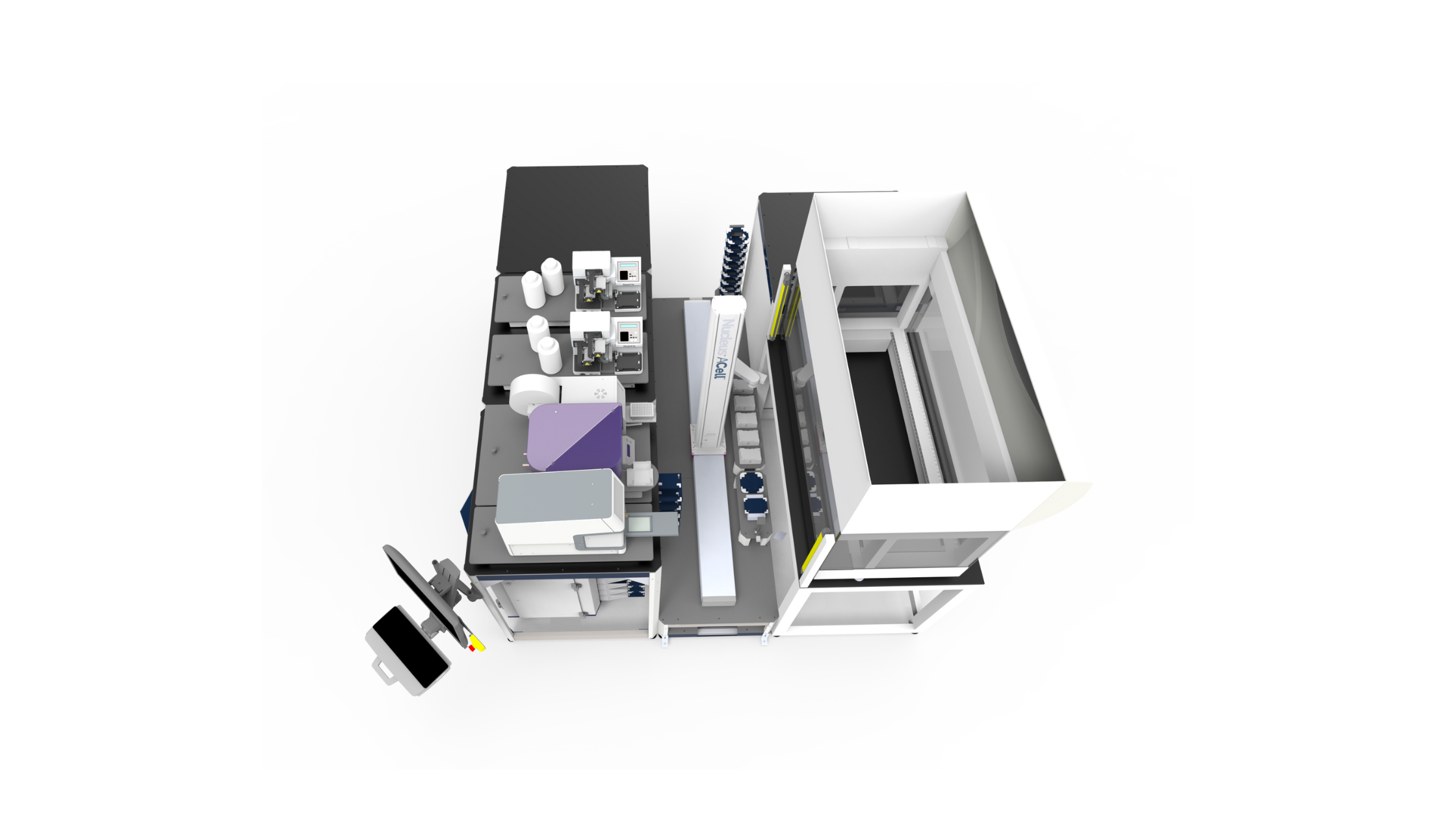

Figure 1. HighRes DNA Amplification and Genotyping System

Workflow Goals: Reliable, Scalable Infinium XT Processing

This system was designed with the following operational objectives in mind:

- Consistent Amplification – Automating DNA pre-amp protocols across 24+ plates per run.

- Flexible Dispensing – Supporting both disposable and fixed-tip pipetting with optional non-contact dispensing.

- Throughput Expansion – Enabling runs of 24 plates in under 8 hours, with protocol variants simulated for increased capacity.

- Traceability – Barcode scanning, plate orientation, and Cellario tracking across all workflow stages.

- Minimal Operator Burden – Integrated hotels, decappers, and storage modules reduce touchpoints.

System Architecture: Modular and Expansion-Ready

The system build integrates a combination of HighRes and partner technologies, anchored by rail-mounted robotics and Cellario scheduling.

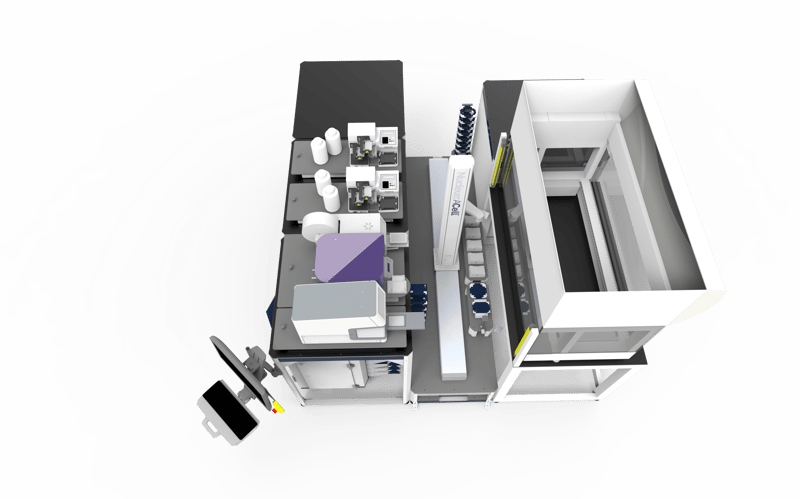

Figure 2. HighRes DNA Amplification and Genotyping System Design

Figure 2. HighRes DNA Amplification and Genotyping System Design

Key Components:

- ACell Robot on Rail – Provides high-speed plate movement across the work cell.

- HighRes AmbiStore D – Ambient plate storage with multiple stacker configurations.

- Tecan Fluent 780 – Core liquid handler with configurable pipetting heads and under-deck reservoirs.

- Dispensing Options – Two BioTek Multiflo FX units or integration with a Tempest non-contact chip dispenser for low-volume additions.

- Plate Processing Modules – Azenta A4S sealer, Azenta Automated Plate Seal Remover (formerly Brooks XPeel®), Micronic CS700 decapper.

- Specialized Devices – HighRes MicroSpin with automated balance swapping, multiple shakers, barcoding (Keyence SR1000W, PlateOrient).

- Expansion Path – Nucleus tables and additional incubators (Cytomat, Liconic) allow scaling into chilled/controlled environments.

Workflow Example: Infinium XT Pre-Amp

Representative protocols were modeled and simulated in Cellario to demonstrate throughput and performance:

- Single-Plate Protocol (Disposable Tips) – Sequential processing with estimated throughput of 10 plates in ~8h 44m.

- Dual-Plate Protocol (Fixed Tips) – Parallel processing doubles throughput to 24 plates in ~7h 24m.

- Quad-Plate Protocol (Fixed Tips + Multiflo/Tempest) – High-throughput variant achieving 24 plates in ~5h 44m, or as fast as 3h 54m with non-contact dispensing.

Smart Scheduling with CellarioScheduler

CellarioScheduler automates parallel device execution and provides clear visualization via Gantt charts. The software enables:

- Parallelization – Fluent pipetting, plate shaking, and sealing overlap across plates.

- Throughput Simulation – Run times modeled with historical device timing data.

- Bottleneck Management – Scheduler staggers movements to avoid queueing at sealers and decappers.

- Scalability – Labs can expand capacity simply by running more plates in parallel without re-engineering.

Figure 3. CellarioScheduler Protocol Simulation of 24 plates in 3:53:41 (hh:mm:ss)

Figure 3. CellarioScheduler Protocol Simulation of 24 plates in 3:53:41 (hh:mm:ss)

Software Integration: Ready for CellarioOS

Beyond scheduling, the system is designed for CellarioOS orchestration:

- Integration with LIMS for full traceability of plate and sample lineage.

- Real-time adjustments via pacing and flow control.

- Flexibility to incorporate future modules (e.g., magnetic bead processing or compound storage).

Summary & Benefits

This representative Infinium XT system illustrates HighRes’ approach to automating genotyping workflows:- Flexible Throughput – From single-plate reliability to quad-plate high throughput.

- Future-Proof Design – Expansion options for storage, shakers, and dispensers.

- Smart Scheduling – Optimized resource usage, with predictive throughput visualization.

- Seamless Integration – Ready for CellarioOS orchestration, LIMS connectivity, and advanced reporting.

At HighRes, we co-design workflows that scale with your science. Tell us about your project today!