This Nucleus system represents a modular approach to cell-based screening that adapts to your laboratory's evolving needs. Designed with good accessibility and room for expansion in a compact footprint (10 x 6 ft or 3.1 x 1.8 m) and flexible configuration options, this system exemplifies how modern automation can scale alongside your research programs without requiring extensive facility renovations or large capital investments upfront.

If you are attending SLAS2026 in Boston, we will be showing live demos of this system on the exhibition floor. Visit Booth #1408 at SLAS!

Our Philosophy: Built for Real-World Labs

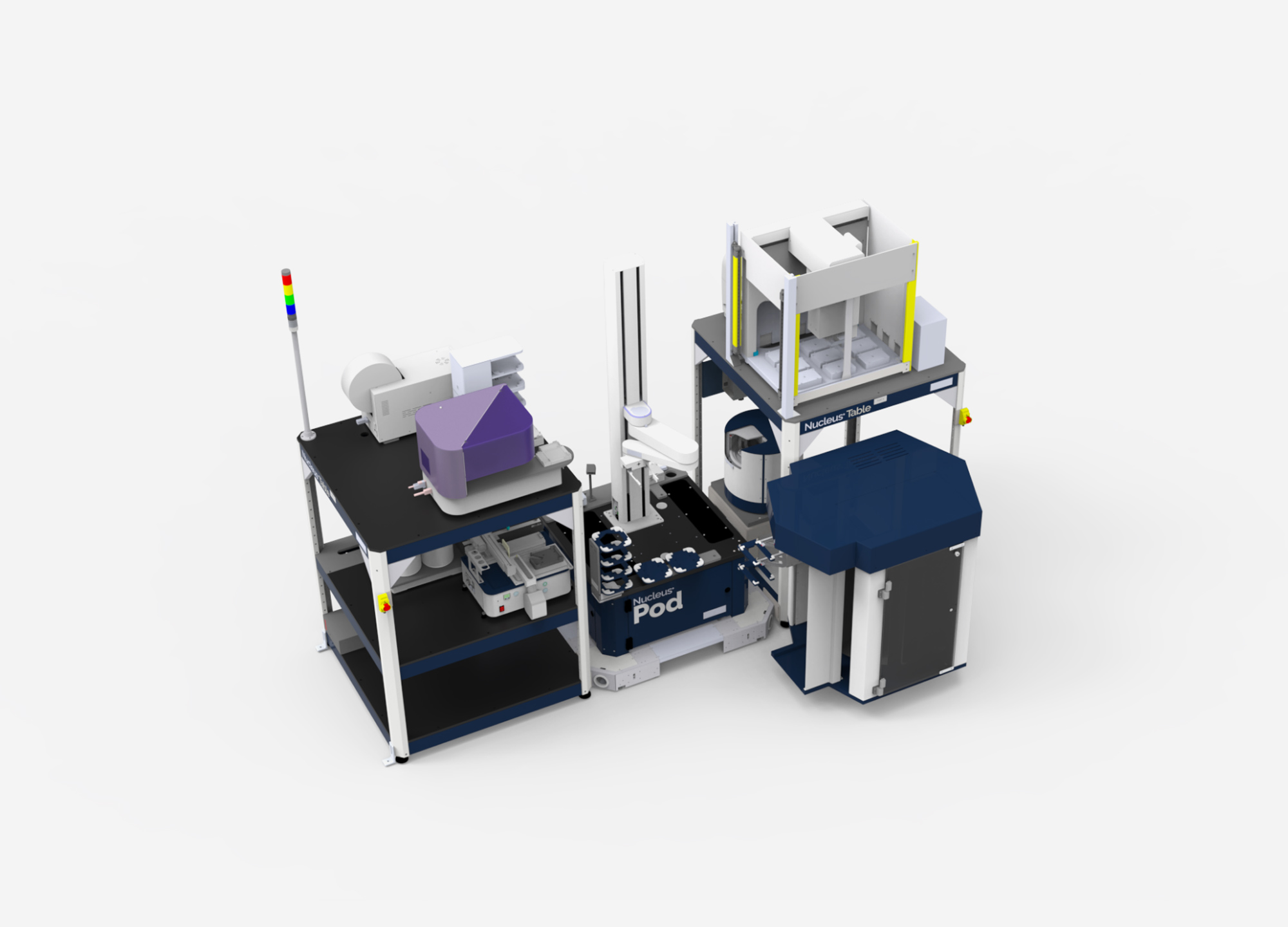

Unlike monolithic automation platforms, the Nucleus System embraces modularity as a core design principle. The configuration showcased demonstrates a representative customer deployment – not a maximalist showcase, but rather the kind of practical setup that laboratories implement and use daily. This particular build balances capability with accessibility, featuring the collaborative ACell robotic arm with advanced perception capabilities while maintaining a relatively small laboratory footprint (Fig. 1).

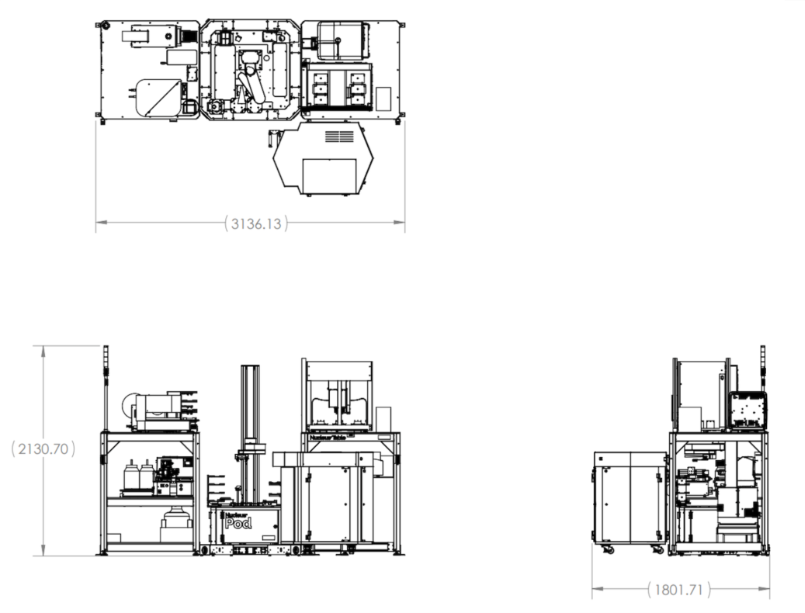

Figure 1. System design drawing of this flexible Nucleus Pod high-throughput screening system which takes up 10 x 6 ft (3.1 x 1.8 m).

The system's design acknowledges a fundamental reality of laboratory automation: your needs will change. Screening protocols evolve, throughput requirements shift, and new assay types emerge. Rather than forcing you to work around static infrastructure, the Nucleus System is designed to grow and reconfigure as your laboratory does.

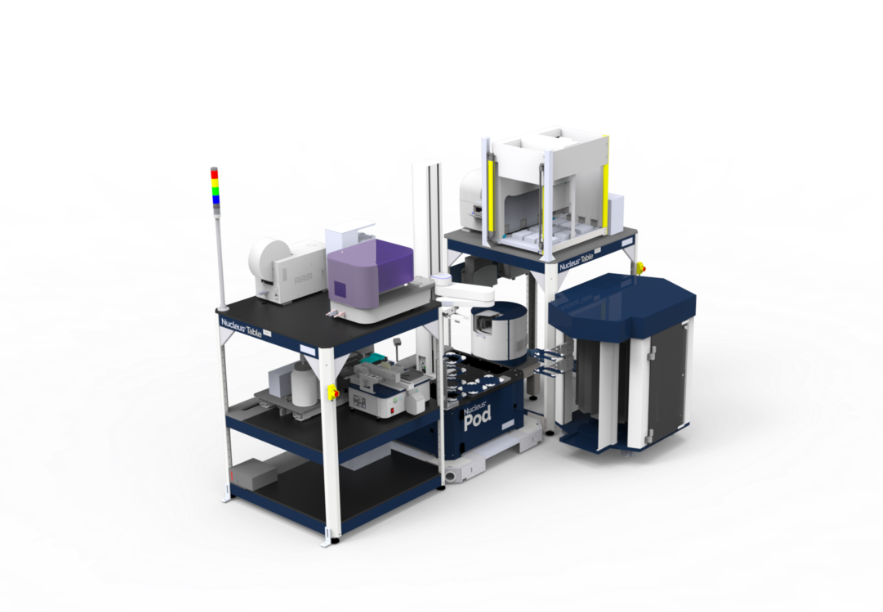

Figure 2. Rendering of the screening system, featuring the HighRes Nucleus Pod and ACell Robotic Arm, including integrated instruments like the Agilent Bravo Liquid Handler, Azenta XPeel Plate Peeler, Azenta A4S Plate Sealer, and more.

True Hands-Off Operation

Once configured and loaded, the system can execute complex multi-step screening protocols autonomously and concurrently, freeing your scientific staff from repetitive plate handling and allowing them to focus on data analysis and experimental design.

Distributed Intelligence

Importantly, this integration isn't confined to a single physical location. Components can be distributed across your laboratory space and still operate as a cohesive system, with the robotic arm transporting materials between stations as needed. This means you can integrate existing instruments you already own, maximizing your previous investments rather than replacing everything.

System Design

This system configuration includes:

Liquid Handling & Dispensing:

- Agilent Bravo Liquid Handler (96-well head)

- HighRes PreciseDrop II (PDII) Non-Contact Dispenser

Plate Processing:

- Azenta XPeel Plate Peeler

- Azenta A4S Plate Sealer

- HighRes PreciseWash Plate Washer (Coming Soon!)

- HighRes MicroSpin Automated Centrifuge

Incubation & Detection:

- 2x QInstruments Bioshake 3000 elm (96-well plate shakers)

- Agilent BioTek Synergy Plate Reader

Plate Management:

- 2x LidValet units

- 5-position Plate Hotel (for buffering)

- AmbiStore D Ambient Storage

Automation:

- ACell collaborative robotic arm with vision capabilities

- Agilent PlateLoc precision plate positioning system

The Nucleus Lab Automation Platform Concept

Nucleus is a modular laboratory automation platform designed to scale with science. Paired with Cellario Platform, Nucleus is a powerful platform that brings standardized hardware, workflows, data, and HighRes expertise together into a single, cohesive system. You can design your ideal Nucleus system by combining flexible, interoperable components into a solution tailored to your science.

One of the most significant advantages demonstrated across the systems we are showcasing at SLAS2026 is the flexibility in robotic arm placement. Unlike traditional automation platforms where the robot is permanently fixed in a single configuration, this Nucleus System can accommodate various robot options and mounting positions.

Choose Your Robot: Every Nucleus system begins with a collaborative robotic arm selected to support laboratory automation workflows. These standard robots are used to move plates and labware safely and efficiently between instruments, forming the operational core of each automated workcell. Robots can be mounted on a stationary pod, table, or integrated with a linear rail that extends reach across multiple tables and carts. The result is a flexible foundation that can be configured for current workflows and expanded as automation needs grow.

Reconfigurable Architecture: Robots aren't locked into a single mounting position. Depending on your specific workflow and laboratory layout, you can position and reposition the arm to optimize reach, cycle time, and integration with your existing equipment.

Future-Proof Investment: Adapt your system as science changes. Instruments can be exchanged, layouts adjusted, and workflows expanded using modular components and repeatable interfaces. With standardized mounting and MicroDock-based positioning, your workcell can be reconfigured predictably and efficiently. Scale capacity, introduce new instruments, or shift workflows without disrupting operations or rebuilding the system.

This flexibility extends to the Nucleus table configurations themselves, which can be customized based on device size, type, and your preferred arrangement, allowing you to build the system around your workflow rather than adapting your workflow to fit the system.

Modularity in Practice

The system's modularity manifests in several practical ways:

- Device Configuration: Shelving and device placement can be easily modified. Need to add a new reader or swap out a liquid handler? The system accommodates reconfiguration without requiring a complete redesign.

- Storage Scalability: As your screening needs change and grow, storage can be easily swapped or upgraded. The AmbiStore D shown in this configuration is ideal for biochemical screening and endpoint cellular assays that don't require environmental control. For more demanding cellular screening applications requiring 37°C and CO2 incubation, the system readily accommodates environmental storage options like the SteriStore or LiCONiC incubators. Additional storage modules can also be added as throughput requirements increase.

- Table Expansion: Multiple Nucleus tables can be deployed and integrated as your needs grow, allowing you to pack additional devices around the pod in configurations optimized for your specific device inventory.

- Workflow Evolution: As screening protocols mature or change, the system can be adapted, adding processing stations, incorporating new device types, or reorganizing the workflow sequence without discarding your existing investment.

Safety and Simplicity

While this configuration maintains a relatively straightforward design, optional safety features such as tower lights and emergency stops can be integrated based on your facility's requirements and risk assessments. The system prioritizes showcasing the core pod and table options rather than advanced safety enclosures, but these capabilities are available for deployment environments that require them.

The Nucleus System's modular architecture makes it suitable for a wide range of screening applications. The configuration shown at SLAS2026 is optimized for biochemical screening workflows and endpoint cellular assays that can be performed at ambient temperature.

For laboratories conducting more complex cell-based screening requiring environmental control, the system architecture readily supports integration of CO2 incubation capabilities. While we couldn't bring environmental incubation to the show floor, adding SteriStore or LiCONiC incubators to this configuration would enable the full spectrum of cellular screening applications, from primary cell-based assays to multi-step compound toxicity elimination workflows.

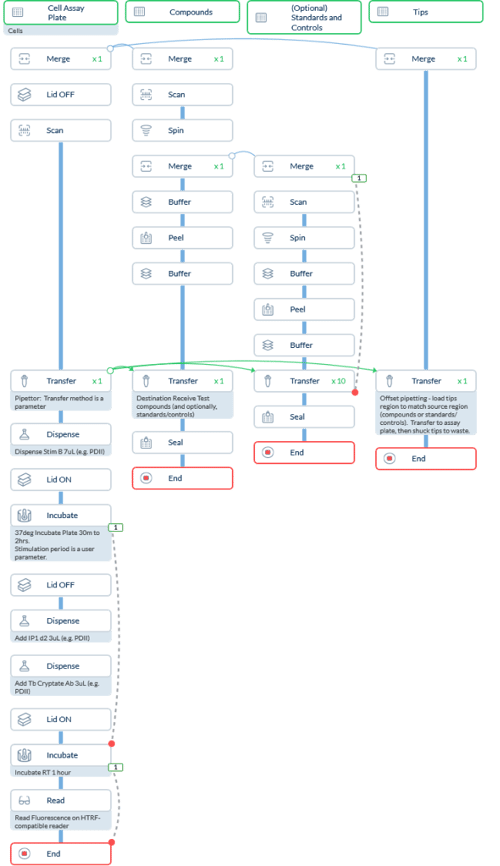

The workflow logic that we've simulated demonstrates the system's capability for complex screening cascades: primary cell-based screen IP-1 (Fig. 3; Fig. 6) → Eliminate toxic compounds with CellTiter-Glo (Fig. 4; Fig. 7) → Confirm mechanism with biochemical assay with Transcreener (Fig. 5; Fig. 8). This progression moves from broad functional screening to mechanistic confirmation, which is a standard funnel approach in drug discovery screening cascades.

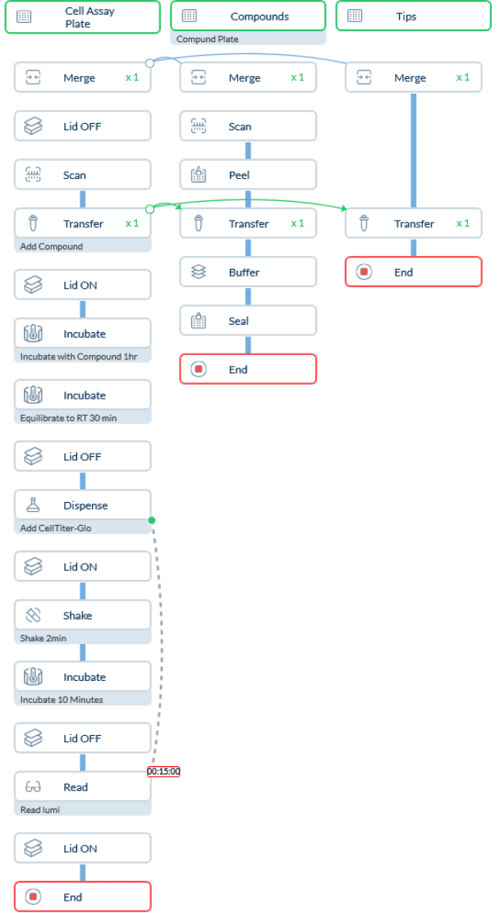

Figure 3. Simulated CellarioScheduler Protocol Design for IP-1 Gq assay.

Figure 4. Simulated CellarioScheduler Protocol Design for CellTiter-Glo assay.

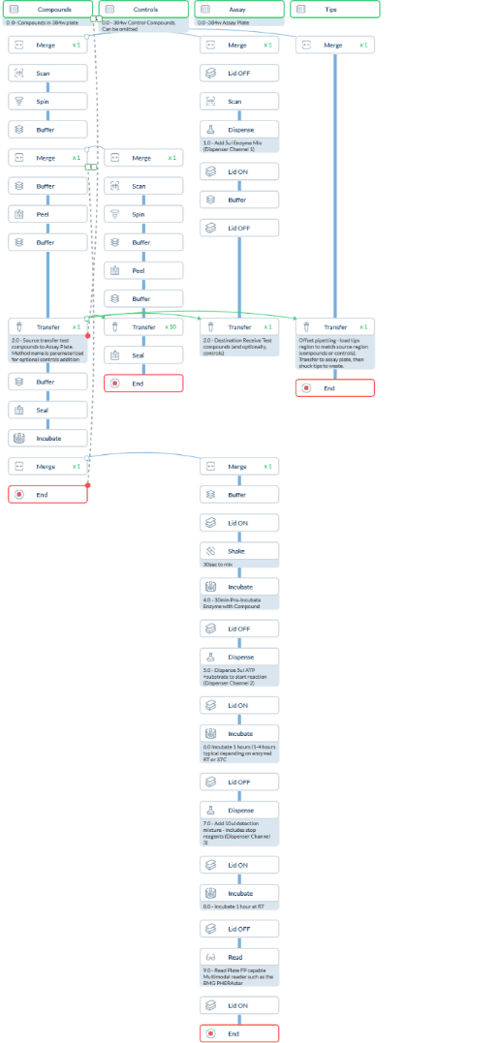

Figure 5. Simulated CellarioScheduler Protocol Design for Transcreener assay (FP).

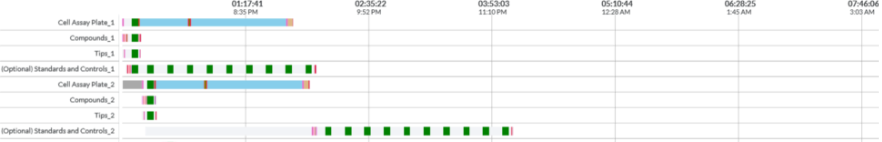

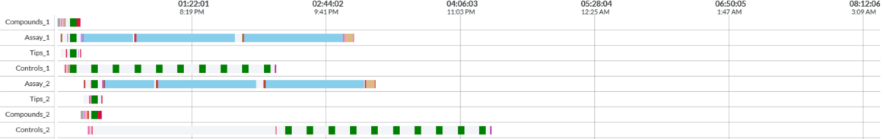

Figure 6. Simulated IP-1 Gq assay Gantt Chart in CellarioScheduler.

Figure 7. Simulated CellTiter-Glo assay Gantt Chart in CellarioScheduler.

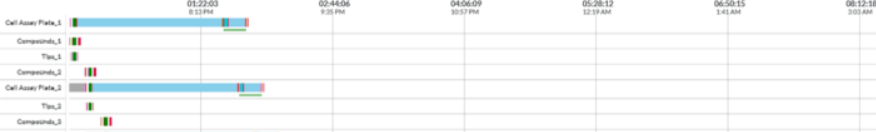

Figure 8. Simulated Transcreener assay (FP) Gantt chart in CellarioScheduler.

Protocol development and scheduling are managed through comprehensive Gantt chart-based planning in CellarioScheduler, allowing you to visualize and optimize complex multi-step workflows before deployment.

CellarioScheduler's intuitive protocol definition enables you to focus on logical steps and dependencies rather than low-level device commands, reducing development time while increasing clarity and maintainability. Our scheduling software manages timing, dependencies, and resource contention automatically, enabling true parallel execution where multiple protocols can run simultaneously across shared resources. Built-in simulation tools let you validate execution plans and identify potential bottlenecks or timing conflicts before committing samples or reagents, while robust error handling ensures the system can resolve common faults and adapt execution paths to keep workflows moving while preserving data integrity.

Conclusion

This Nucleus System designed for screening embodies a pragmatic approach to laboratory automation: start with what you need today and expand as your lab or your science grows. Its compact footprint makes it accessible to laboratories that lack extensive floor space, while its modular architecture ensures you won't outgrow the platform as throughput demands increase.

By showcasing a representative customer configuration rather than an aspirational maximum, this system demonstrates that sophisticated, truly autonomous screening is achievable within the constraints of real-world laboratories. The configuration at SLAS2026 highlights the system's biochemical screening capabilities and flexibility to accommodate environmental control for cellular applications.

Whether you're establishing your first automated screening capability or looking to modernize an existing platform, this Nucleus System offers a pathway that balances immediate functionality with long-term flexibility, allowing your automation infrastructure to evolve alongside your science. Tell us about your project or visit us and see this system in action at SLAS2026!